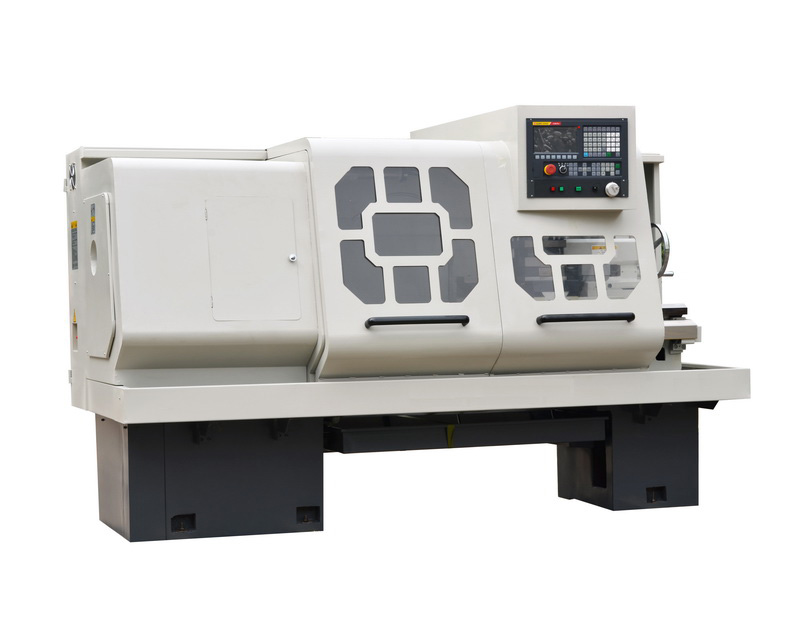

CKH50Y is high efficient and economic CNC lathe. It can turn cylindrical surface, taper surface, arc surface, internal hole, slots and threads, and is suitable for single or mass production of parts.

△ The bedway is hardened and precision ground.

△ Spindle speed-change combines 2-position manually with VF.

△ The machine is high in rigidity and accuracy, runs smoothly with low noise.

△ Large output torque at low speed.

● Siemens CNC system

● 3-jaw chuck

● Lighting system

● Automatic lubricating system

● Cooling system

● 4-station electric toolpost

※ FANUC CNC system

※ Pneumatic or hydraulic chuck

※ Steady rest

※ Follow rest

※ Gang-type tool holder

※ Live center

|

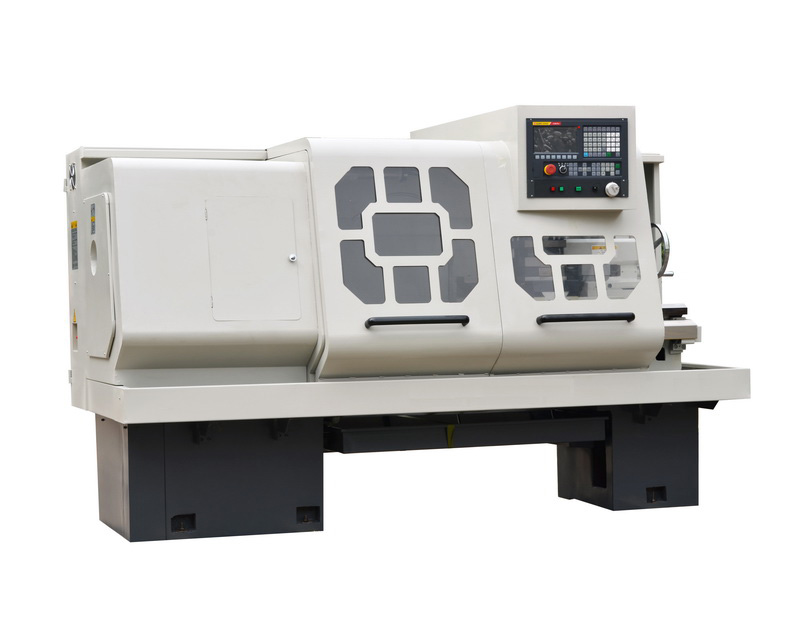

Specification |

Unit |

CKH50Y |

|

Max. swing diameter over bed |

mm |

500 |

|

Max. swing diameter over table |

mm |

250 |

|

Spindle speed |

rpm |

50-1600 |

|

Spindle bore |

mm |

72 |

|

Spindle taper |

|

1:20 |

|

Distance between centers |

mm |

1000 |

|

Max. longitudinal stoke |

mm |

940 |

|

Max. cross stoke |

mm |

250 |

|

Tailstock stroke |

mm |

128 |

|

Tailstock taper |

|

MT5 |

|

Turning tool size |

mm |

25*25 |

|

Rapid feed |

m/min |

X:6/Z:6 |

|

Circle |

mm |

0.005/300 |

|

Cylinder |

mm |

0.03/300 |

|

Power of motor |

kW |

7.5 |

|

Min. setting unit |

mm |

0.001 |

|

Repositioning accuracy |

mm |

X: 0.012/Z: 0.016 |

|

N.W./G.W. |

kg |

2130/2350 |

|

Overall dimensions |

mm |

2650*1300*1680 |