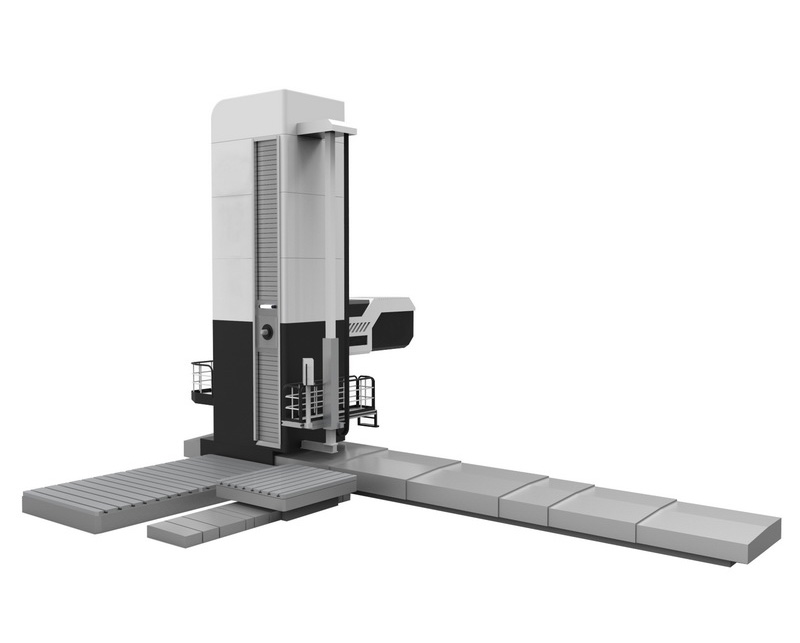

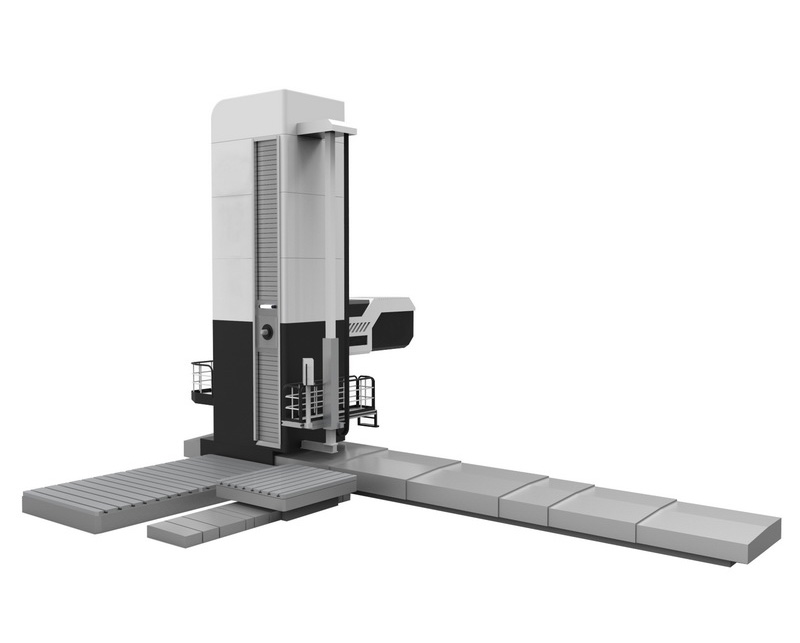

TKF series CNC floor type milling & boring machine adopt finite element optimum design, with functions of boring, drilling, tapping, groove milling, plane milling, etc.

Equipped with function attachments such as high precision CNC rotary table, right angle milling head, the machine can realize 5 surfaces machining. It is the idea equipment for processing steam turbine, generator and heavy duty machine tools in industries of metallurgy, power and electricity, etc.

△ Spindle bearing adopts constant flow hydrostatic bearing, with advantages of heavy loading capacity,

low heat dissipation, and long term accuracy stability

△ X,Y,Z axis adopt “pump per pocket” type hydrostatic guideway of constant flow

△ Double rack and pinion transmission for clearance elimination, and preloaded ballscrew transmission

△ Headstock balancing adopts electro-hydraulic compensation mechanism

△ Auto diagnoses function for convenient operation

|

Specification |

Unit |

TKF200 |

TKF225 |

TKF260 |

TKF320 |

|

Spindle Dia. |

mm |

φ200 |

φ225 |

φ260 |

φ320 |

|

Spindle Taper |

ISO |

60 |

60 |

60 |

|

|

Spindle Speed |

r/min |

2.5-800 |

1.6-800 |

2.5-1000 |

|

|

Shift number of Spindle Gear |

|

4 |

4 |

3 |

|

|

Max Spindle Torque |

Nm |

16000 |

20000 |

25000 |

|

|

Size of End of Milling Spindle |

mm |

φ330 |

φ350 |

φ400 |

φ470 |

|

Ram Section |

mm |

460*550 |

620*740 |

800*950 |

|

|

Main Motor Power |

kW |

100 |

100 |

130 |

|

|

Column Travel(X axis) |

mm |

6000+n*1000 |

6000+n*1000 |

6000+n*1000 |

|

|

Headstock Vertical Travel (Y axis) |

mm |

4000-6000 |

5000-9000 |

6000-12000 |

|

|

Ram Travel(Z axis) |

mm |

1200 |

1600 |

2500 |

|

|

Spindle Travel(W axis) |

mm |

1250 |

1700 |

1800 |

|

|

Overlay Travel of Spindle and Ram |

mm |

2450 |

3300 |

4300 |

|

|

Column Movement Speed(X axis) |

mm/min |

0.1-8000 |

0.1-5600 |

0.1-6000 |

|

|

Headstock Vertical Speed (Y axis) |

mm/min |

0.1-5600 |

0.1-5600 |

0.1-6000 |

|

|

Spindle Movement Speed (W axis) |

mm/min |

0.1-4500 |

0.1-4800 |

0.1-6000 |

|

|

Ram Speed(Z axis) |

mm/min |

0.1-4500 |

0.1-4800 |

0.1-6000 |

|

|

Measurement System |

|

HEIDENHAIN |

HEIDENHAIN |

HEIDENHAIN |

|

|

CNC System |

|

SIEMENS 840DSL |

SIEMENS 840DSL |

SIEMENS 840DSL |

|