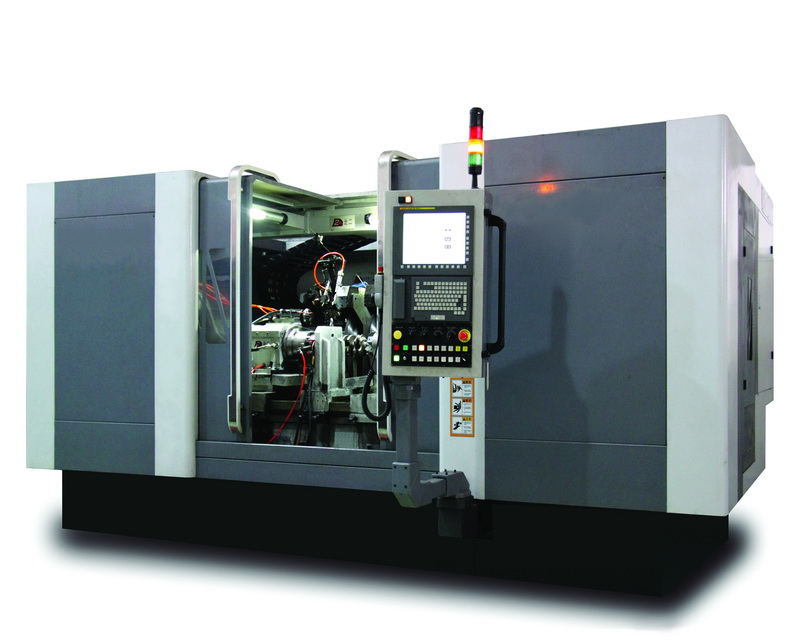

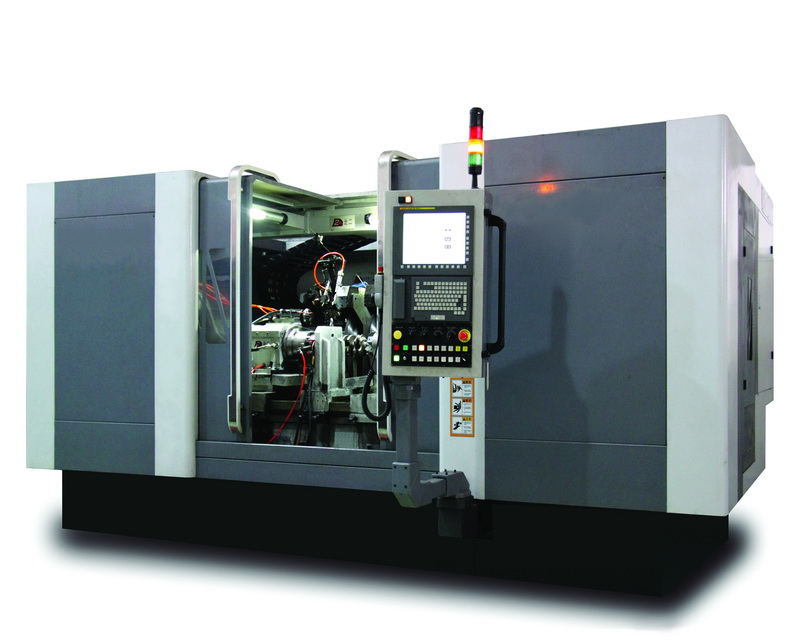

△ Follow-up swing type grinding rod journal

△ On-line measurement under full closed loop control

△ One-time clamping to ensure the accurate batch processing of the rod journal, main journal and thrust surface of the crankshaft.

△ Linear speed of the CBN grinding wheel can reach 120m/s.

△ Wheel head (X1 and X2 axis) is driven by linear servo motor and equipped with closed hydrostatic guideway.

△ Fast forward speed reaches 40m/min

△ High rotation and positioning accuracy

△ Advanced international famous brand active measuring device

△ Specific grinding interface software

|

Specification |

Unit |

MKQ52T |

|

|

Maximum rotating diameter |

mm |

Φ520 |

|

|

Distance between Centers |

mm |

600/1200 |

|

|

Height of center |

mm |

350 |

|

|

Maximum grinding diameter |

mm |

Φ320/Φ400 |

|

|

Maximum workpiece weight between centers |

kg |

150 |

|

|

Control System |

|

FANUC SIEMENS |

|

|

Grinding wheel (max) |

OD × W × ID |

mm |

Φ650×(16-80)(CBN) |

|

Linear speed |

m/sec |

120 |

|

|

Wheel head(X axis) |

Total travel |

mm |

400 |

|

Feed speed |

mm/min |

0.01~60000 |

|

|

Minimum setting unit |

mm |

0.001 |

|

|

Backward lower sliding table (Z axis) |

Type |

|

Backward longitudinal movement |

|

Feed speed |

mm/min |

0.02~20000 |

|

|

Minimum setting unit |

mm |

0.001 |

|

|

Work head |

Center |

|

Special purpose chuck |

|

Rotating speed |

rpm |

0-200(stepless) |

|

|

Tailstock |

Center |

|

Special purpose chuck |

|

Rotating speed |

rpm |

0-200(stepless) |

|

|

Travel of center |

mm |

100 |

|

|

Electrical system |

Power of wheel spindle motor |

kW |

~30 |

|

Feeding of wheel head |

|

Linear motor |

|

|

Feeding of backward sliding table |

N.m |

30 |

|

|

Accuracy |

Roundness |

mm |

0.003mm/0.005mm |

|

Consistency of the longitudinal section diameter |

mm |

0.004mm/0.006mm |

|

|

Roughness |

μm |

Ra 0.32;Ra 0.63 (end face) |

|

|

Total power |

kW |

~160 |

|

|

Net Weight |

kg |

~25000 |

|