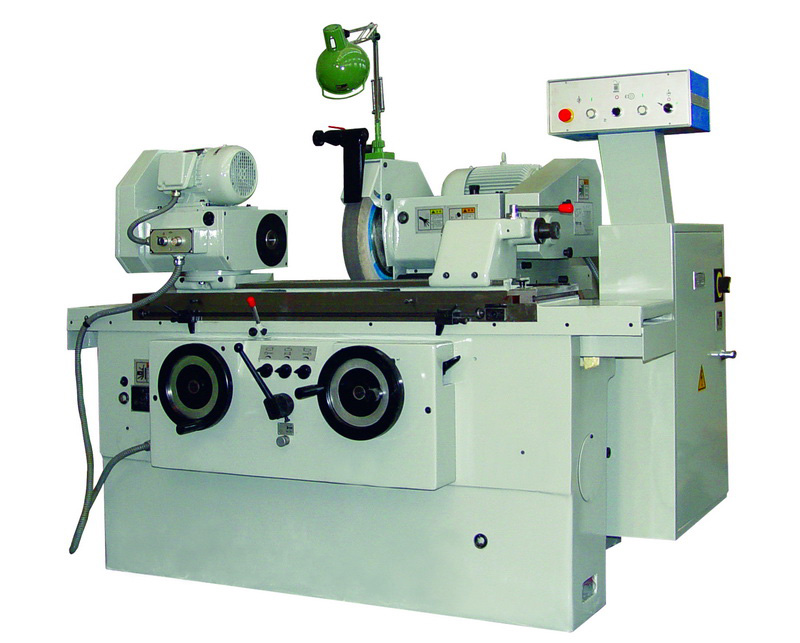

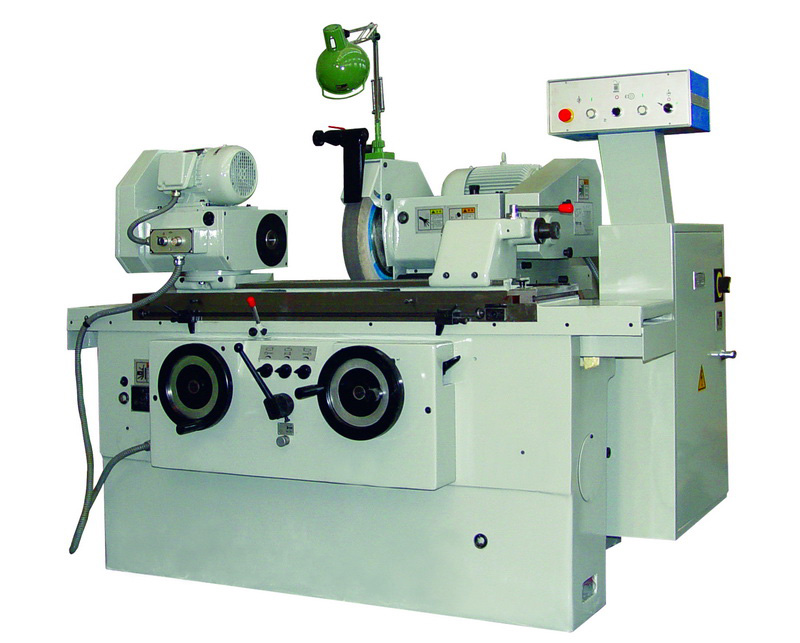

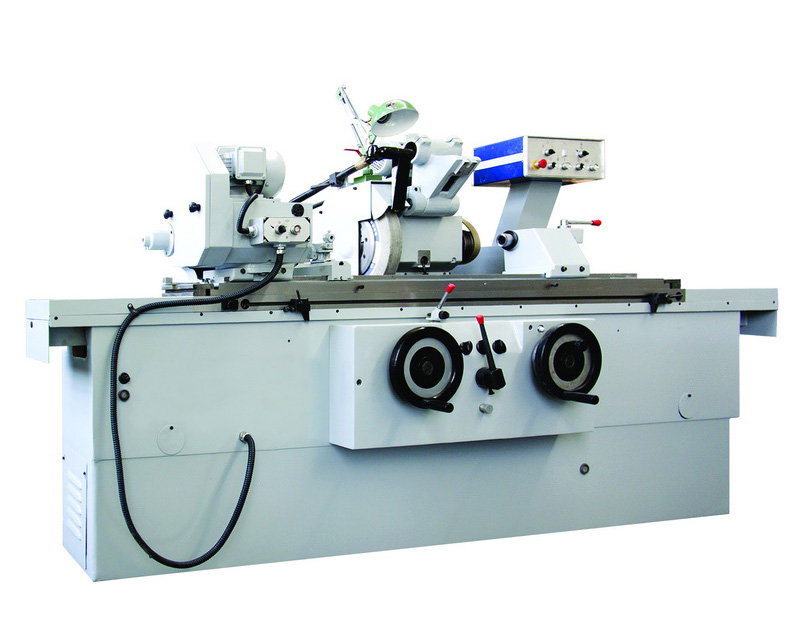

△ With high machining precision,the integral layout of machine tool is rational, appearance is attractive, operating handles are

centralized arranged and visualization, thus to make the machine easy to control and safe to operate.

△ The wheel head adopts a structure of sleeve type bearing bush hydrodynamic bearing main shafting and features high rotary

precision and high rigidity.

△ The feeding guideway uses antifriction & plastic-filming guideway, thus promoting the smoothness and vibration resistance of

low-speed operations.

△ The hydraulic drive system uses screw pump which is of smooth running and low noise.

△ MCB (semi-automatic) grinding machines can perform plunge-cut grinding or longitudinal grinding to conduct small-lot or batch

production under the control of fixed distance or automatic measuring device.

△ For the MCB (semi-automatic) grinding machines, their grinding functions and action sequences of processing cycle are

controlled by programmable logic controller (PLC).

● Balancing mandrel

● Wheel balancing stand

● Three - jaw chuck(Only for universal machines)

●Internal grinding attachment(Only for universal machines)

● Wheel flange

● Coolant tank

● Stand grinding wheel dresser

※ Closed center rest

※ Open center rest

※ Four - jaw chuck

※ Automatic measuring device(Only for semi - automatic machines)

|

Specification |

Unit |

MC20U MC20UB |

MC32U MC32UB |

MC20S MC20SB |

MC32S MC32SB |

|||||||||

|

Height of center |

mm |

125 |

180 |

125 |

180 |

|||||||||

|

Distance between Centers |

mm |

520 |

765 |

1050 |

520 |

765 |

1050 |

520 |

765 |

1050 |

520 |

765 |

1050 |

|

|

Maximum swiveling diameter |

mm |

240 |

350 |

240 |

350 |

|||||||||

|

Maximum grinding length |

mm |

500 |

750 |

1000 |

500 |

750 |

1000 |

500 |

750 |

1000 |

500 |

750 |

1000 |

|

|

Range of external grinding |

mm |

Φ5-Φ200 |

Φ5-Φ320 |

Φ5-Φ200 |

Φ5-Φ320 |

|||||||||

|

Range of internal grinding |

mm |

Φ13-Φ80 |

Φ16-Φ125 |

- |

- |

|||||||||

|

Depth of internal grinding(over 45mm) |

mm |

125 |

160 |

- |

- |

|||||||||

|

Maximum workpiece weight |

kg |

50 |

||||||||||||

|

Grinding wheel |

OD×W×ID |

mm |

400×(32~50)×203 |

|||||||||||

|

Max. linear speed |

m/sec |

35 |

50 |

|||||||||||

|

Swiveling angle |

Clockwise |

|

9° |

8° |

3° |

9° |

8° |

3° |

9° |

8° |

3° |

9° |

8° |

3° |

|

Counter-clockwise |

|

9° |

8° |

7° |

9° |

8° |

7° |

9° |

8° |

7° |

9° |

8° |

7° |

|

|

Taper hole |

Work head |

|

Morse4# |

|||||||||||

|

Tailstock |

|

Morse4# |

||||||||||||

|

Total power |

kW |

6.6 |

6.6 |

6 |

6 |

|||||||||

|

Net weight |

kg |

2500 |

3100 |

2750 |

2500 |

3100 |

2750 |

2500 |

3100 |

2750 |

2500 |

3100 |

2750 |

|

|

Net weight |

kg |

3000 |

3600 |

2870 |

3000 |

3600 |

2870 |

3000 |

3600 |

2870 |

3000 |

3600 |

2870 |

|

|

Overall |

Length |

mm |

3500 |

4100 |

3700 |

3500 |

4100 |

3700 |

3500 |

4100 |

3700 |

3500 |

4100 |

3700 |

|

Width |

mm |

2000 |

||||||||||||

|

Height |

mm |

2100 |

||||||||||||