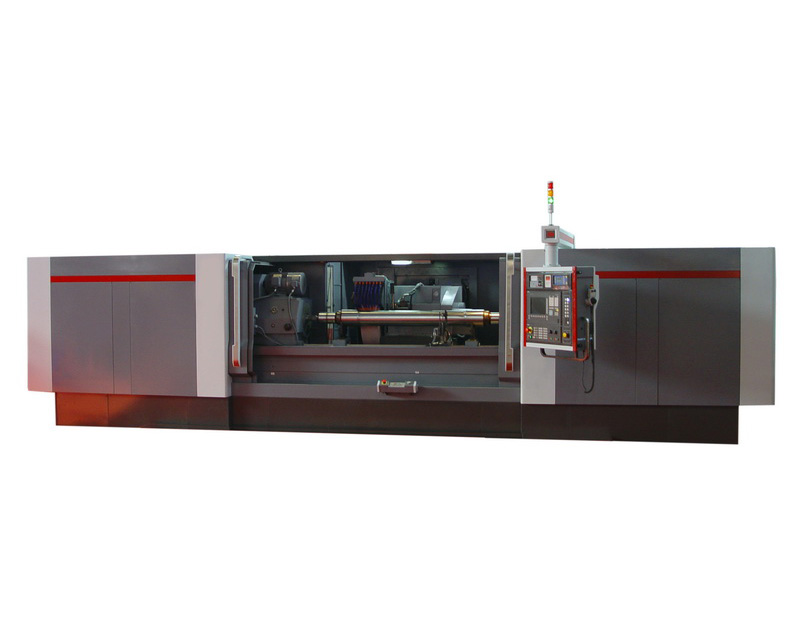

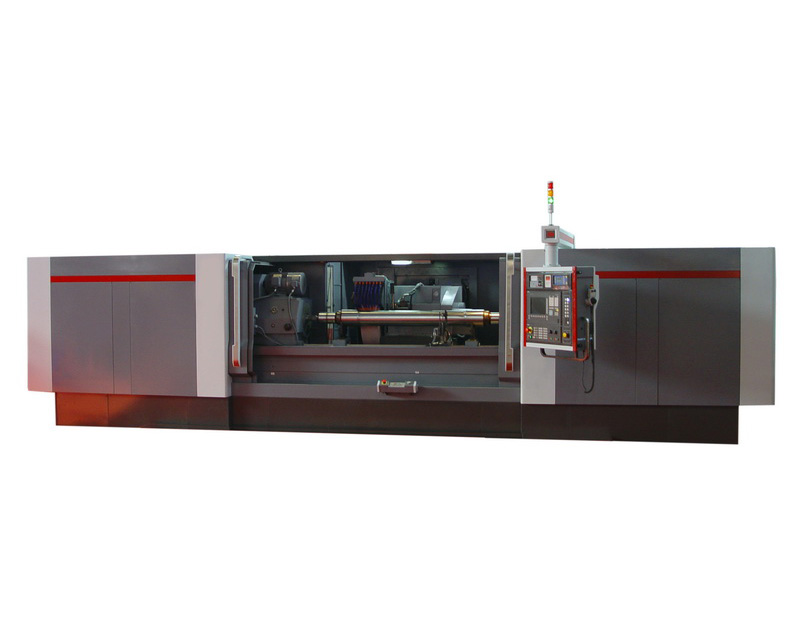

MKC and MKCE CNC cylindrical grinding machines are large-size CNC machine tools independently designed, developed and manufactured through the Company’s import, digestion and absorption of overseas & domestic advanced technologies. They are characterized by the universalization, high-degree modularization, high rigidity, high efficiency and high adaptability. Being large-size CNC cylindrical grinding machines of convenient operations, reliable performance and high processing precision, the series of machine tools are suitable for production occasions with batches or bulks of production for parts of large-size shaft types.

△ With the rational layout and integral protective cover, the machine is convenient for maintenance and in conformity with human

engineering requirements.

△ The grinding wheel spindle adopts a structure of sleeve type high-rigidity hydrostatic/hydrodynamic mainshafting and features on

its high rotary precision and strong bearing capacity. The linear velocity of the grinding wheel can be up to 60m/s (specially

ordered).

△ With two-axis linkagefeeding, the machine tool is equipped with worktable(Z axis) and wheel head(X axis) drivenby AC

servomotor and ball screws. With plastic-filming guidewaybeing used and on the adoption of the closed multi-points lubrication, it

features vibration absorbing and anti-friction as well as good precision maintenance.

△ The machine can be provided with various diamond dressers according to customers' needs, thus realizing precise dressing of

complex grinding wheel surfaces and automatic compensation.

△ Equipped with an imported or a domestic active measuring device, the closed-loop control of grinding process is realized.

△ Adopting an imported advanced CNC system, the machine features on the menu type interface input and the control up to four

axes (X, Z, U and U axes) so as to meet the requirements of grinding and dressing cycles.

△ The machine may optionally equipped with a CNC or a hydraulic driven auto-tracing central rack dedicated for processing of long

and thin shaft parts.

|

Specification |

Unit |

MKC50/MKC63 |

MKCE50/MKCE63 |

|||||||

|

×15 |

×20 |

×25 |

×30 |

×15 |

×20 |

×25 |

×30 |

|||

|

Maximum rotating diameter |

mm |

Φ540/Φ670 |

Φ540/Φ670 |

|||||||

|

Distance between centers |

mm |

1500 |

2000 |

2500 |

3000 |

1500 |

2000 |

2500 |

3000 |

|

|

Height of center |

mm |

275/335 |

275/335 |

|||||||

|

Maximum grinding diameter |

mm |

Φ500/Φ630 |

Φ500/Φ630 |

|||||||

|

Maximum workpiece weight between centers |

kg |

1000/2000 |

||||||||

|

Control System |

|

FANUC SIEMENS |

||||||||

|

Grinding wheel(max) |

OD × W × ID |

mm |

Φ750×120~200×Φ305 |

|||||||

|

Φ900×100×Φ305 |

||||||||||

|

Linear speed |

mm/sec |

45/60 |

||||||||

|

Wheel head |

Total travel |

mm |

390/450 |

|||||||

|

Feed speed |

mm/min |

0.1~5000 |

||||||||

|

Minimum setting unit |

mm |

0.001 |

||||||||

|

Oblique angle |

° |

90 |

60 |

|||||||

|

Worktable |

Type |

|

Two layer conical degree adjusting worktable |

|||||||

|

Feed speed |

mm/min |

0.1~5000 |

||||||||

|

Minimum setting unit |

mm |

0.001 |

||||||||

|

Work head |

Center |

|

MT.NO6/metric 80 |

|||||||

|

Rotating speed |

rpm |

15-150(stepless) |

||||||||

|

Tailstock |

Center |

|

MT.NO6/metric 80 |

|||||||

|

Travel of center |

mm |

70 |

||||||||

|

Electrical system |

Power of wheel spindle motor |

kW |

18.5/22 |

|||||||

|

30/37 |

||||||||||

|

Torque of wheel head feeding motor |

N.m |

22(FANUC)/27(SIEMENS) |

||||||||

|

30(FANUC)/36(SIEMENS) |

||||||||||

|

Torque of worktable feeding motor |

N.m |

22(FANUC)/27(SIEMENS) |

||||||||

|

30(FANUC)/36(SIEMENS) |

||||||||||

|

Power of work head spindle motor |

kW |

4/5.5 |

||||||||

|

Hydraulic pump motor |

kW |

0.75(4P) |

||||||||

|

Motor of wheel spindle bearing lubrication pump |

kW |

0.75(4P) |

||||||||

|

Cubage dimension |

Hydraulic and lubricating oil tank |

L |

45/75 |

|||||||

|

Spindle bearings oil tank |

L |

45/75 |

||||||||

|

Net Weight |

t |

11/14 |

12/16 |

13/18 |

14/20 |

11/14 |

12/16 |

13/18 |

14/20 |

|