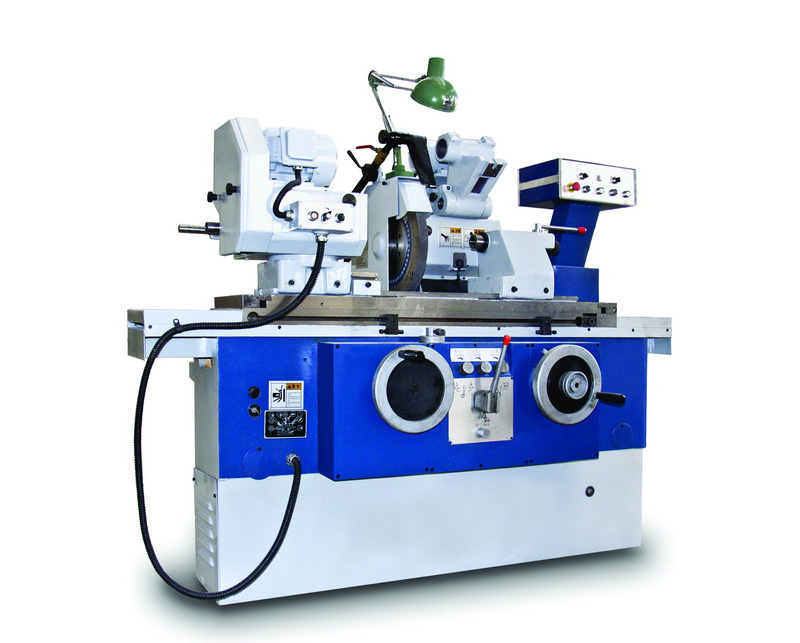

△ With the screw pump adopted in the hydraulic drive system and it gains features of smooth running and low running noise

△ Equipped with sleeve type big conical degree hydrodynamic bearing shafting with integral bearing bush in wheel head, high

rotary precision and rigidity are realized

△ The feeding guideway uses antifriction & plastic-filming guideway, thus promoting the smoothness and vibration resistance of

low-speed operations

△ Besides the advantages of high machining accuracy, reasonable overall layout and attractive appearance, the operating handles

of the machine are centralized arranged and visualization, thus to make the machine easy to control and safe to operate

△ With the function of semi-automatic plunge-cut grinding and longitudinal grinding controlled by the sizematic grinding or automatic

measuring instrument, the machine of MCPB type (high-precision semi-automatic) can be used for processing small-lot or

batched high-precision parts

△ For the MCPB type machine (high-precision semi-automatic), all the grinding functions and sequence of operation in the

processing cycle are controlled by PLC

●Balancing mandrel

●Wheel balancing stand

●Three - jaw chuck (Only for universal machines Φ130)

●Internal grinding attachment (Only for universal machines)

●Wheel flange

●Coolant tank (Optional magnetic coolant separator is available)

●Stand grinding wheel dresser

※ Closed center rest

※ Open center rest

※ Four - jaw chuck

※ Automatic measuring device (Only for semi - automatic machines)

※ Paper filter (High precision machine tool accessory)

|

Specification |

Unit |

MC20P MC20PB |

MC32P MC32PB |

MC20UP MC20UPB |

MC32UP MC32UPB |

|||||||||

|

Height of center |

mm |

125 |

180 |

125 |

180 |

|||||||||

|

Distance between centers |

mm |

520 |

765 |

1050 |

520 |

765 |

1050 |

520 |

765 |

1050 |

520 |

765 |

1050 |

|

|

Max. swiveling Dia. of the workpiece |

mm |

240 |

350 |

240 |

350 |

|||||||||

|

Maximum grinding length |

mm |

500 |

750 |

1000 |

500 |

750 |

1000 |

500 |

750 |

1000 |

500 |

750 |

1000 |

|

|

Range of cylindrical grinding |

mm |

5-200 |

5-320 |

5-200 |

5-320 |

|||||||||

|

Range of internal grinding |

mm |

- |

- |

13-80 |

16-125 |

|||||||||

|

Maximum internal grinding depth |

mm |

- |

- |

125 |

160 |

|||||||||

|

Maximum workpiece weight between centers |

kg |

50 |

||||||||||||

|

Grinding wheel |

OD ×W×ID |

mm |

400×(32~50)×203 |

|||||||||||

|

Max. linear speed |

m/sec |

35 |

||||||||||||

|

Swiveling angle |

Clockwise |

|

9° |

8° |

3° |

9° |

8° |

3° |

9° |

8° |

3° |

9° |

8° |

3° |

|

counter-clockwise |

|

9° |

8° |

7° |

9° |

8° |

7° |

9° |

8° |

7° |

9° |

8° |

7° |

|

|

Taper hole |

Work head |

|

Morse 4# |

|||||||||||

|

Tailstock |

|

Morse 4# (Morse 3# as optional) |

||||||||||||

|

Total power of machine tool |

kW |

7 |

7 |

7.5 |

7.5 |

|||||||||

|

Net weight of the machine tool |

kg |

2500 |

3000 |

3500 |

2500 |

3000 |

3500 |

2500 |

3000 |

3500 |

2500 |

3000 |

3500 |

|

|

Gross weight of the machine tool |

kg |

3100 |

3600 |

4100 |

3100 |

3600 |

4100 |

3100 |

3600 |

4100 |

3100 |

3600 |

4100 |

|

|

Packing size |

Length |

mm |

2800 |

2900 |

3800 |

2800 |

2900 |

3800 |

2800 |

2900 |

3800 |

2800 |

2900 |

3800 |

|

Width |

mm |

2200 |

||||||||||||

|

Height |

mm |

2200 |

||||||||||||